In the realm of woodworking, your choice of woodworking materials holds immense significance. There are two primary wood categories to consider: softwoods and hardwoods.

Softwoods like pine and cedar are budget-friendly and suitable for beginners, offering valuable wood selection tips, although they may lack durability.

Hardwoods such as oak, maple, and cherry are robust, perfect for sturdy projects, and exhibit beautiful grain patterns.

It's vital to select wood that aligns with your project's requirements and your skill level, as it can greatly influence the outcome.

In your wood shop, selecting the right wood is pivotal. Factors to contemplate include project type, budget, desired aesthetics, durability, and workability.

Your choice of wood sets the tone for your woodworking project's success.

When choosing wood, liken it to selecting paint, as it establishes the project's ambience.

Consider:

Wood Choices: Opt for oak for a sturdy dining table or pine for easy shelves.

Grain Patterns: Oak offers bold grain, while cherry presents a subtler appearance. Be mindful of grain direction, as it affects the project's style.

Now, let's delve into eco-friendly woodworking. It's not just a trend; it's responsible.

Sustainable Forestry: Prioritize wood sourced from responsibly managed forests to safeguard trees and woodlands.

Reclaimed Wood: Breathe new life into aged wood, infusing character while reducing the demand for fresh timber, benefiting both your project and the environment.

Opting for eco-conscious wood choices allows you to create exquisite pieces while preserving our planet's invaluable resources.

Time to embrace woodworking!

Consider these guidelines:

Storing and Acclimating: Maintain wood in a dry, well-ventilated space, allowing it to adapt to your workspace for a few days. It is recommended to stack boards with small (10–15mm) spacers between them. If not, they may rot or lose their colour. Do not stack flat on the cement, but rather on a level surface.

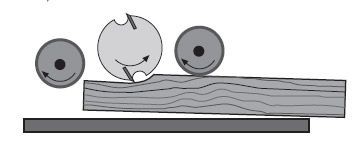

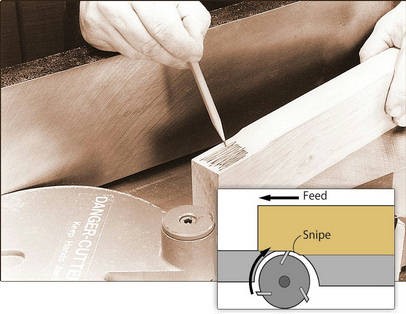

Cutting, Planing, and Sanding: Precision is paramount. Employ sharp tools, measure meticulously, and work with care. Effective planning and diligent sanding enhance the final finish.

Dealing with Warped Boards: Warped boards can pose challenges. Utilise jigs or clamps to rectify them or explore alternative options to save time and effort.

With these insights, you'll shape raw wood into your envisioned woodworking creation. Happy crafting!