Over the past thirty years, woodworking has progressed remarkably, but amid this evolution, one tool has emerged as a game-changer in workshops—the portable router. Its versatility and diverse applications have elevated it to an indispensable companion for woodworking enthusiasts, whether professional or DIY. This article explores the multifaceted capabilities of the portable router, ranging from shaping edges to intricate inlay work, while also providing crucial insights into safety precautions and factors to consider when purchasing this tool.

Unlocking the Portable Router's Extensive Abilities:

The portable router is a genuine workhorse that can undertake an impressive array of tasks, revolutionizing woodworking by introducing a new level of precision and creativity. Below are just a few examples of its remarkable abilities:

Edge Forming: Effortlessly craft classic beading or intricate ogee profiles, enhancing the refined aesthetics of your woodworking projects.

Lap Joints: Establish seamless connections through lap joints, reinforcing the structural integrity of your creations.

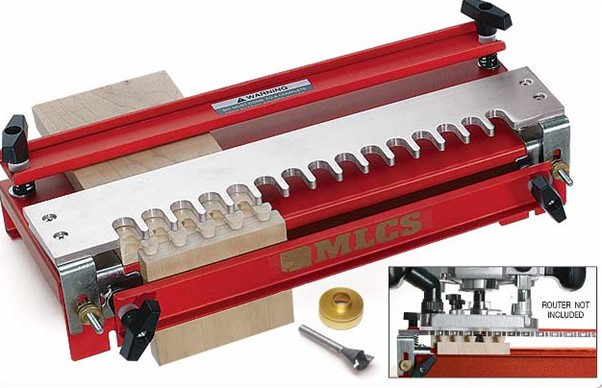

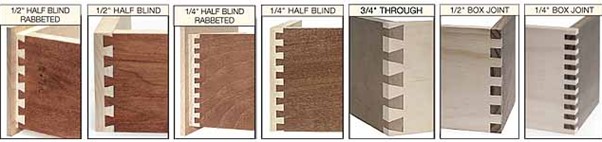

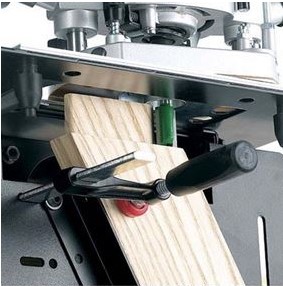

Dovetail Joints: Employ the router's precision to create dovetail joints, renowned for their strength and visual appeal in fine woodworking.

Rebates: Achieve immaculate rebates, ensuring components fit flawlessly together and contributing to a seamless finish.

Carving and Lettering: Unleash intricate carving and lettering possibilities, transforming ordinary surfaces into personalized artistic expressions.

Inlay Work: Elevate your woodworking projects to a museum-worthy level with captivating inlay designs that showcase your craftsmanship.

Laminate Trimming: Achieve smooth, professional laminate edges, using the router's precision for impeccable trimming.

Mortise and Tenon Joints: Craft accurate mortise and tenon joints for enduring connections that withstand the test of time.

Fitting Mortise Door Locks and Door Hinges: Attain precise fits for door locks and hinges, ensuring seamless door functionality.

Ellipse and Circle Cutting: Seamlessly cut precise ellipses and circles, adding distinctive shapes to your creations.

Trenching and Dadoes: Achieve grooves and dadoes with exceptional precision, catering to shelving and other joinery requirements.

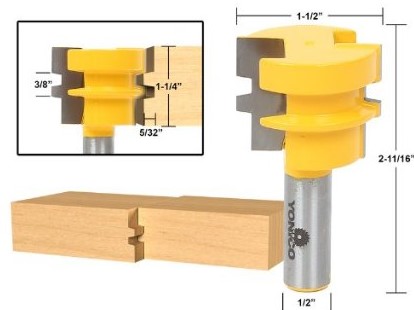

Glue Joints: Employ the router to create tight-fitting glue joints, enhancing the strength and durability of your projects.

Style and Rail Joints for Raised Panel Doors: Showcase your woodworking finesse by crafting classic raised panel doors with elegant style and rail joints.

Panel Raising: Introduce dimension and elegance to cabinet doors and panels through distinctive raised panels.

Post-Form Top Joining: Enhance furniture aesthetics and functionality by creating seamless joins for post-form tops.

Prioritizing Safety During Router Operation:

Despite its power, safety remains paramount when operating a router. Adhering to these safety guidelines ensures incident-free woodworking sessions:

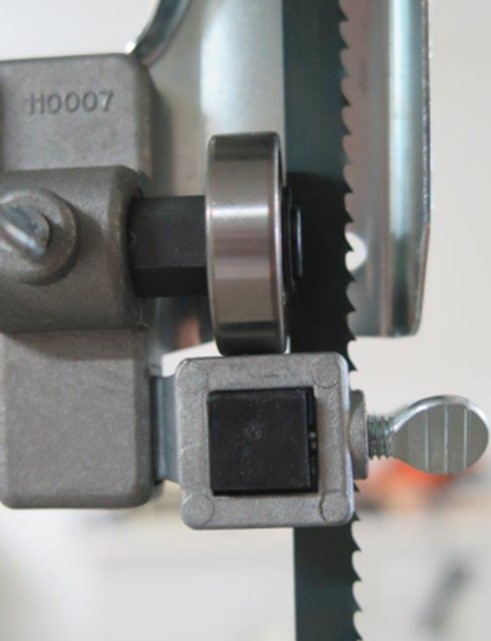

Clean Collet: Regularly clean the collet to maintain a secure bit grip, preventing any compromise due to dust or grime accumulation.

Proper Bit Insertion: Insert the router bit with around 2/3rds of the shaft securely held by the collet, paying heed to any depth indicators.

Two-Handed Operation: Maintain control and stability by always gripping the router with both hands when the motor is active.

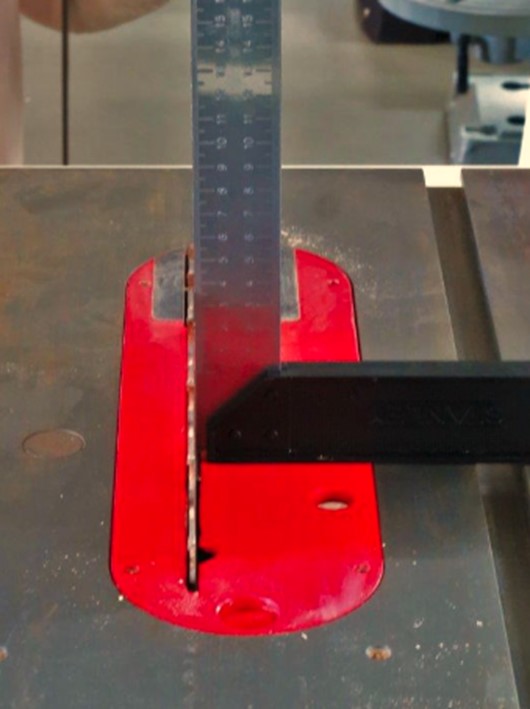

Feed Rate: Opt for an optimal feed rate; too slow leads to burning, while excessive speed overloads the motor. A medium rate delivers optimal outcomes.

Cutting Direction: For enhanced control and precision, consistently cut against the cutter's rotation direction.

Bit Maintenance: Keep bits sharp and clean, utilizing a flat diamond grit card to sharpen the cutting face's back. Post-use, oil and clean the bit to prevent rust.

Protective Gear: Shield against noise and dust by donning ear defenders and a dust mask, ensuring a safer working environment.

Choosing Router Bits Wisely:

When investing in router bits, quality reigns supreme, impacting performance and durability:

Shank Sizes: In the South African market, router-bit shank sizes commonly come in ¼” and ½”. These diverge from the European 6mm and 12mm counterparts.

Industrial vs. Portable: Heavy-duty ½” shank routers are prevalent in industrial settings, frequently mounted on router tables. Meanwhile, ¼” shank routers offer portability and ease of use.

Quality is Key: Opt for quality over cost when selecting router bits. Superior bits boast smoother bearings and better tungsten carbide, ensuring longevity and precision.

In Conclusion:

The portable router has rewritten the possibilities of woodworking, endowing a broad spectrum of capabilities that enhance craftsmanship. From intricate designs to seamless joints, this adaptable tool broadens horizons in both creativity and accuracy. By adhering to safety protocols and investing in high-quality bits, your woodworking journey with the portable router is bound to be gratifying and productive.