Are you weary of dedicating endless hours to manual sanding of flat panels, doors, and components? Drum sanders can be the quick fix you've been looking for. We will examine the many benefits of drum sanders in this blog and provide some priceless tips to ensure you get the most out of these amazing machines.

Drum Sanders: Revolutionizing the World of Woodworking

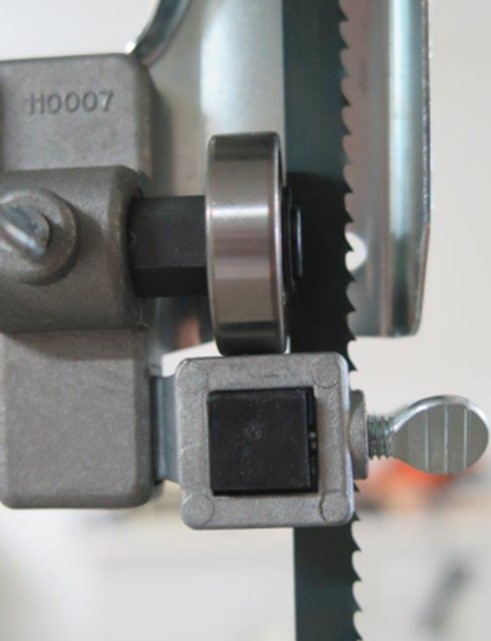

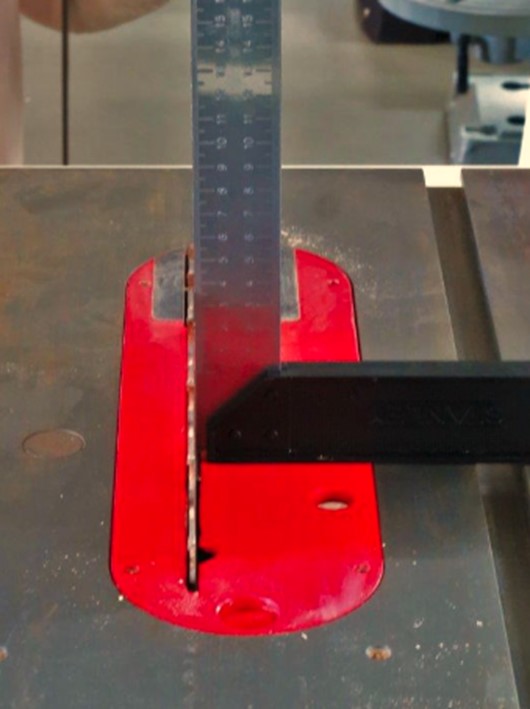

Imagine obtaining equal thickness while sanding your materials, a feat that was previously thought to be impossible using traditional sanding techniques. Drum sanders accomplish that. Their genius is in the mechanism; a revolving drum expertly controls the sanding operation while a black conveyor belt softly moves your stuff through the device. These are some crucial advantages:

Uniform Thickness:

Drum sanders shine in their ability to uphold a consistent thickness, a task fraught with difficulty using alternative sanding techniques.

Adjustable Feed Rate:

You wield control over the feed rate, granting you the capability for precision sanding. For that ultimate, impeccable finish, opt for fine paper in tandem with a slow feed rate.

Economical Sandpaper Usage:

These sanders utilize 75mm wide strips of sandpaper that can be effortlessly substituted in just about 2 minutes. Bid farewell to pricey tailor-made sleeves!

Ideal for Delicate Materials:

Drum sanders prove ideal for delicate materials. You can even craft your veneer by amalgamating a band saw with a drum sander. Wood can be honed to a paper-thin perfection.

Oscillating Motion (Jet 2244OSC):

Certain drum sanders, such as the Jet 2244OSC, encompass an oscillating drum. This drum not only revolves but also sways laterally about 25mm. This ingenious feature thwarts the emergence of undesirable tramlines in the final product, contingent on the type of wood employed.

Superlative Craftsmanship:

When you invest in a drum sander, you're essentially investing in precision. Manufacturers like Jet go to great lengths to ensure the feed table remains perfectly level, ensuring absolute accuracy in your projects.

Expert Tips for Maximizing Drum Sander Performance

Now that you've been introduced to the marvels of drum sanders, here are some seasoned tips to optimize their efficiency:

Sand in Both Directions:

For an even finer finish, experiment with sanding in the opposite direction while maintaining the same settings. This technique often yields superior results, as attested by many seasoned woodworkers.

Consider a Rubber Belt Cleaner:

To prolong the lifespan of your sandpaper, contemplate utilizing a rubber belt cleaner. This unassuming tool effectively cleans the sandpaper by gently pressing a rubber stick against the revolving drum. However, its efficacy may be diminished in the presence of substantial resin buildup.

Prioritize Dust Extraction:

Safety takes precedence! Drum sanders generate a significant volume of dust. The use of a dust extractor not only ensures a tidy workspace but also dramatically extends the longevity of your sandpaper.

In conclusion, drum sanders are a game-changing tool for the woodworking industry. They not only give you precision while saving you time, but they also produce amazing outcomes. Keep these expert pointers in mind to elevate the performance of your drum sander, making your woodworking endeavours a breeze. If you have the necessary equipment and knowledge, you can strive for greatness in woodworking. Have fun sanding!