In the realm of woodworking and the pursuit of successful project outcomes, there exists a pivotal but often neglected factor that holds the potential to either elevate or hinder your results: the choice of the appropriate blade. The importance of choosing the right blade goes beyond mere insignificance; it serves as a crucial factor that directly determines the quality of your cuts and, eventually, influences the success of your project.

Determining Blade Size and Bore Size:

Before delving into the intricacies of blade selection, it is essential to commence with the fundamentals: ascertaining the suitable blade size and bore size for your machinery. These measurements hold a paramount role in ensuring not only optimal performance but also the safety of the operation. The alignment of blade diameter and bore size with your equipment's specifications is imperative to ensure a seamless operation that yields precision cuts.

Factors to Contemplate During Blade Selection:

Beyond the rudimentary attributes of blade and bore dimensions, there lies an array of other elements that beckon your consideration for a well-informed blade choice. Let's begin a thorough investigation of these crucial aspects:

Number of Teeth:

The quantity of teeth adorning a blade exerts a substantial influence on the nature of the cuts attainable. Distinct cutting tasks warrant recommended tooth counts:

24 Teeth: An optimal choice for rip cuts, where the objective is to sever along the wood's grain.

60 Teeth: Tailored for cross cuts, enabling meticulous incisions across the grain's span.

40 Teeth: A versatile selection catering to combination tasks, affording equilibrium between ripping and cross-cutting endeavours.

Kerf Width:

The width of the cut induced by the blade, denoted as kerf width, holds the key to curbing material wastage and energy consumption. Broadly speaking:

Standard Width (3.2mm): Suited for an array of applications.

Smaller Blades (2.5mm): Exhibiting heightened efficiency for smaller tasks, they conserve power and economize wood by minimizing material excision.

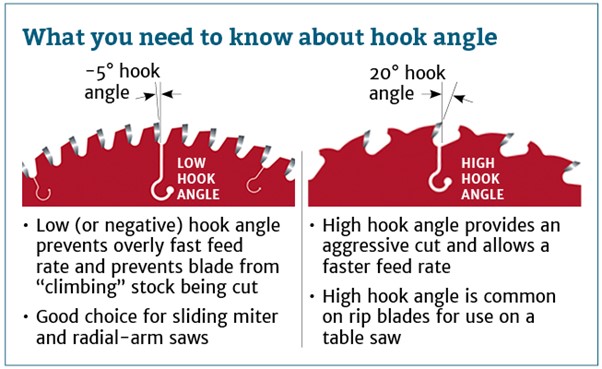

Tooth Rake Angle:

The tooth rake angle plays a substantial role in achieving unblemished and efficient cuts, especially when manoeuvring through various materials. Insights into this aspect encompass:

Negative Rake Angle: Employed for cutting non-ferrous metals like aluminium. Proper lubrication with bobbing grease is imperative to thwart binding. A negative rake paired with diamond-shaped teeth proves effective for cleanly cutting melamine boards sans chipping.

Positive Rake Angle: Essential for table saws, delivering a seamless feed rate.

Low/Negative Rake Angle: Tailored for radial arm saws and mitre saws, serving as a preventive measure against any unwanted ascent during cross cuts.

Blade Height and Acuity:

Preserving the optimal height of the blade above the wood surface holds paramount importance. During rip cuts, it is imperative to ensure the blade's gullet hovers just above the wood's surface to minimize resistance and ensure safety. Additionally, the utilization of sharp blades is crucial. Dull blades not only compromise the quality of the cuts but also pose safety hazards due to augmented force requisites.

In Closing:

The process of choosing the most suitable blade for your cutting tasks goes beyond merely selecting the most convenient option. A wise choice of blades requires careful consideration of factors such as blade size, tooth count, kerf width, and tooth rake angle. Understanding how these factors affect your cuts enables you to complete woodworking tasks that are safer, more accurate, and incredibly efficient. Remember that safety is the most significant consideration. Using the right safety measures, such as a blade guard, is essential to preventing accidents and guaranteeing a safe and continuous woodworking adventure. So, embrace the art of blade choosing and watch your efforts reach previously unimaginable levels of success!