Taming the Woodworker's Frustration: Defeating the Snipe Challenge

For woodworkers, the word "snipe" carries a lot of connotations and troubles. It is the frustrating imperfection that can ruin the otherwise flawless surface of your lovingly constructed wooden piece. But be assured that there are practical solutions to mitigate the harm it causes. In this blog post, we'll examine the causes of snipe and give you useful tips for reducing its frequency in your woodworking projects.

Unravelling the Mystery of Snipe:

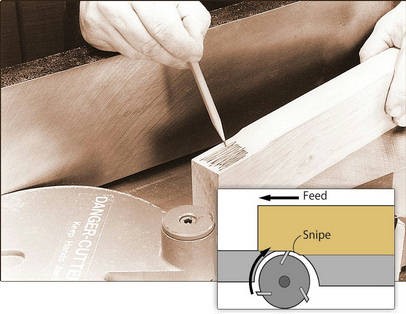

Let's first obtain a thorough understanding of what sniping indicates before moving on to the solutions. Snipe occurs when your workpiece passes through a jointer or planer and a little piece of wood is rapidly removed from the front and/or back of your workpiece. Although it's a great irritation, it wouldn't be fair to put all the responsibility on the machinery. The operator's role can occasionally be crucial in preventing snipe.

Inadequate Support:

Insufficient support for the wood during the machining process ranks among the most prevalent culprits of snipe. To circumvent this issue, consider the following remedies:

Two-Person Approach:

If feasible, involve two individuals in the operation—one stationed at the infeed side and the other at the outfeed side. This arrangement ensures proper wood support and elevation to lay flat on the table.

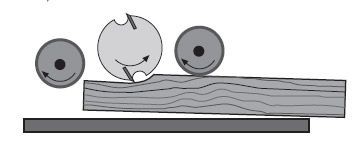

Embrace Support Rollers:

Invest in support rollers; they prove invaluable additions to your workshop. These rollers not only stave off snipe but also prove versatile for various other woodworking tasks. They deliver consistent support and stability to your workpieces.

Mind the Dimensions:

Bear in mind that shorter and straighter wood pieces are less susceptible to snipe. When possible, opt for materials that conform to these specifications to reduce the likelihood of encountering snipe.

Tread Lightly with Tension:

Many machines offer tension adjustment for feed rollers. Exercise caution not to overtighten them, as this can lead to ancillary issues, such as stripped bolts.

Blade Configuration:

Snipe can also rear its head on your surface planer due to blade misalignment. When the blades protrude slightly higher than the outfeed table, they can nibble away at the end of your wood piece. Here's how to address this predicament:

Blade Descent:

In instances of excessively high blade settings, simply lower the blades to bring them into proper alignment with the outfeed table. This adjustment can significantly curtail the occurrence of snipe.

Outfeed Table Adjustment:

Alternatively, you can lower the rear (outfeed) table to facilitate a seamless transition for your wood piece as it exits the planer. This tweak can also serve to eradicate snipe.

In conclusion, snipe represents a vexing challenge for woodworkers, but it's not insurmountable. By grasping its origins and employing the practical solutions outlined here, you can achieve a smoother finish on your woodworking projects. Remember, a touch of extra care and a keen eye for detail can go a long way in consigning snipe to the annals of your workshop's history. Happy woodworking!