Woodworking enthusiasts are aware of how important accuracy is to their artistic vision. Every woodworking workshop is built around the table saw, a multipurpose tool that transforms unfinished lumber into pieces of art. Precision is the key, depending on four fundamental refinements. We'll walk you through these adjustments in this document to make sure your table saw is set up for success.

- Blade Alignment with Mitre Slot Groove: Anchoring Precision

During the inaugural assembly of your table saw, meticulous attention is dedicated to ensuring the blade's alignment with the mitre slot groove. This preliminary synchrony is pivotal for precise incisions. A straightforward technique to evaluate this alignment entails situating a straight edge adjacent to the blade, followed by using a Vernier calliper to compute the distance from the groove to the rule.

If you experience any non-parallelism with the blade, don't be concerned. The screws holding the trunnion assembly to the table must be loosened as part of the adaption operation. You can get precise alignment by carefully manipulating the assembly. It becomes necessary to unbolt the bolts holding the table to the framework and then adjust when certain saw models have an immovable trunnion. The good news is that blade parallelism realignments are rarely required, making this step more common practice for many carpenters.

- Ensuring Fence Synchrony: Priming for Precision Cuts

Fences stand as indispensable components of any table saw, yet their configuration varies amidst diverse models. The fundamental principle remains unaltered: the fence must align in parallel with the mitre slot groove. To achieve this congruence, the utilization of adjustment screws is imperative, which modify the angle between the fence and the fence rail. Give this detail plenty of time to be mastered because a well-matched fence ensures that your workpieces will be carefully guided for flawless cuts.

- Blade Orthogonality to the Table: The Art of Right Angles

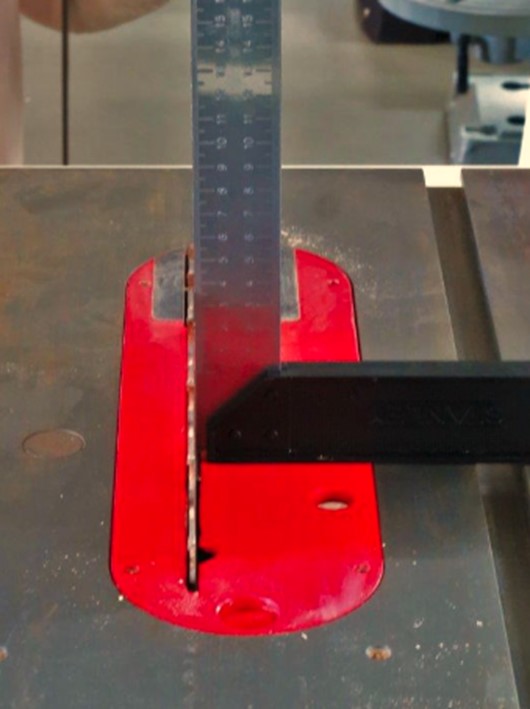

Determining the blade's orthogonality to the table assumes a pivotal role in obtaining square cuts. For this purpose, employ a square in conjunction with the blade. The tilt mechanism of the saw incorporates a casting that engages an adjustment screw upon reaching a stop. Upon this cessation, the blade should manifest an impeccable 90-degree alignment with the table. This tuning guarantees that your incisions are not solely precise but also geometrically congruous.

- Mitre Square Accordance: The Culmination of Adjustments

Making sure your mitre square is perpendicular to the blade is essential for the ideal setup. The use of a square is once again utilized to support this uniformity. You should be able to precisely fine-tune the alignment of your mitre square thanks to adjustment screws. When using the mitre gauge for angled cuts, this step ensures that your workpieces will precisely meet your precision requirements.

Conclusion: Artisanal Excellence via Table Saw Refinements

Your woodworking endeavours demand nothing less than quality, and this pursuit of greatness begins with the accuracy of your table saw. You can set the foundation for accurate and satisfying woodworking projects by becoming a master of these four cardinal adjustments: blade parallelism, fence alignment, blade orthogonality, and mitre square conformity. Remember that even though these details might seem technical, they fundamentally support your woodworking knowledge and allow your creativity to shine through flawlessly finished items.